Understanding Hazards – Plant and Machinery

Machinery hazards can be sub-divided into mechanical hazards and non-mechanical hazards.

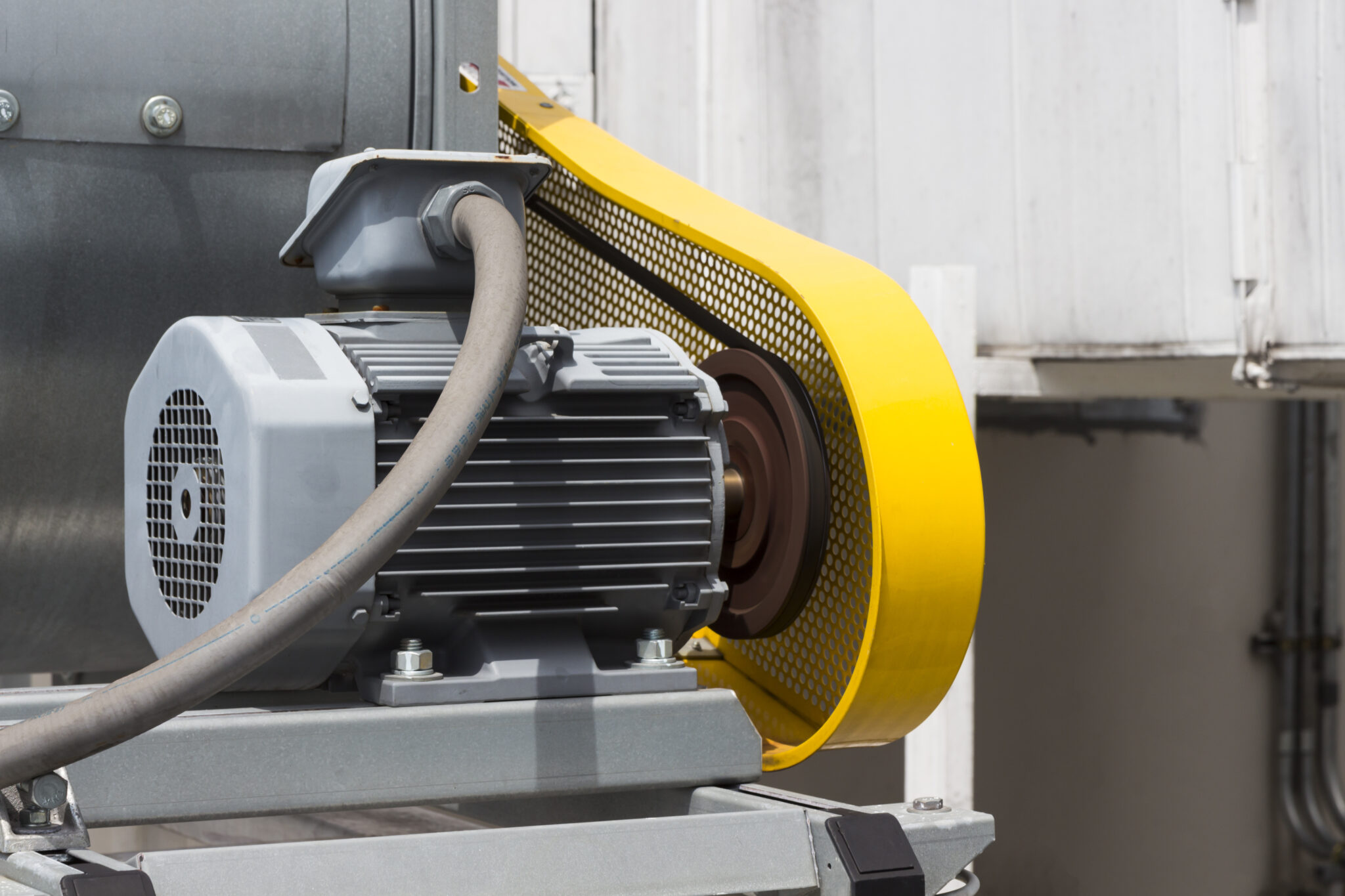

Guarding offers a viable solution for mechanical hazards, if you can’t eliminate or reduce the hazard in any other way. Guards should be chosen in the following order of priority:

Where you don’t need access to the danger zone under normal operation:

• Fixed guard

• Interlocking guard

• Trip device

Where you need access to the danger zone under normal operation:

• interlocking guard

• automatic guard

• trip device

• adjustable guard

• self-adjusting guard

• two-hand control

The condition of plant or machinery should be inspected on a regular basis to ensure that it remains in good condition and all safety features including guards and stop controls are operational.

As a duty holder, you must develop procedures to make sure work equipment is:

• suitable for its purpose

• set-up and used to minimise risks

• well-maintained

• inspected

• operated by trained users